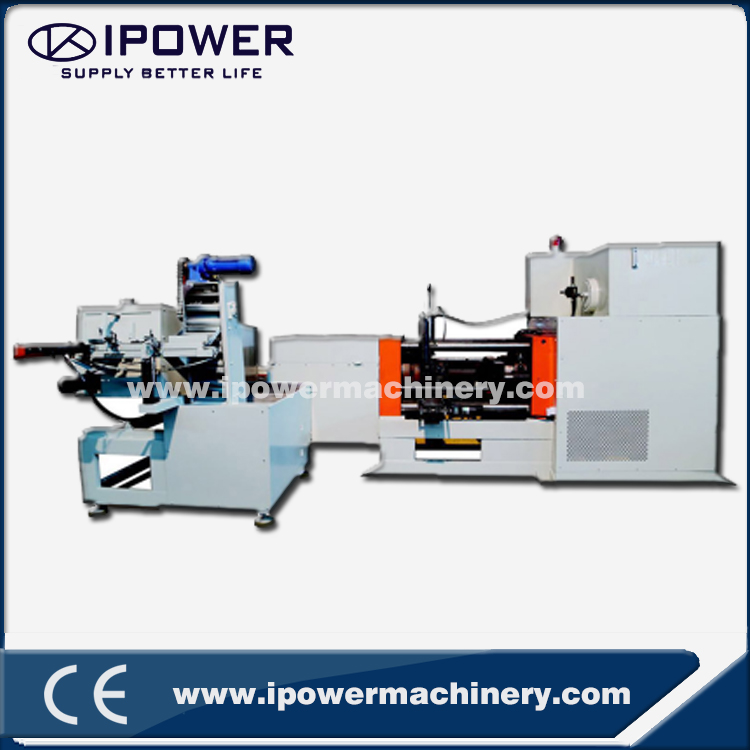

Fully automatic feeding horizontal forging press machine for brass valves, connectors, nipples, screws, caps, cartridges

- Brand: IPOWER

- Type: IP-112T

- Machining Parts: LPG Cylinda Valve, ball valve, plug valve

- Machining Material: Brass,bronze,copper,iron

The machine is mainly used for hot forging technology of brass products, it is highly automtical machine.

The horizontal type of forging press is very suitable for making half mold products(open mold).

The machine working pressure, stroke can be adjusted in the range of the parameters within the

Istp heacsii caadtvioann.tages of simple and flexible operation, low noise, stable pressure, fast movement,high

efficieny,save labor, and cost -effective machine.

The machine is widely used for producing ball valve bodies, gas valve, gate valve,stop valve, check valve,

angle valve pipe fittings and other kind of brass products.

EQUIPMENT PARAMETERS

Model

IPV120SGWL

IPH120SGWL

IPH160SGWL

IPV120YGWL

IPH120YGWL

parameter

Type

Servo vertical

Water cooling

Servo horizontal

Water cooling

Servo horizontal

Water cooling

Ordinary vertical

Water cooling

Ordinary horizontal

Water cooling

Productivity (pcs/min)

25

15

15

25

15

Norminal

Pressure (KN)

1200

1200

1600

1200

1200

Liquid Working Pressure (Mpa)

≦23

≦23

≦23

≦23

≦23

Stamping Stroke

(mm)

220

250

280

220

250

Working Pacing (mm/s)

500

500

500

500

500

Table Size

(mm)

Bofore and after

660

660

680

660

660

Around

750

660

680

760

660

Thickness

120

120

140

120

120

Basic Size (mm)

Length

2975

3550

3600

2975

3550

Width

1465

1750

1750

1465

1750

Boundary Dimension

(mm)

Length

2600

3700

3750

2600

3700

width

1200

1800

1800

1200

1800

Highly

2500

2100

2100

2500

2100

Distance Between Columns (mm)

500

500

510

500

500

Distance between plates (mm)

980

1090

110

980

1090

Platen hole diameter (mm)

230

310

310

230

310

Mold Height (mm)

490

570

550

490

570

Weight (Kg)

3800

4000

4500

3800

4000

Motor Power (Kw)

24

24

37

22

22

Q1:How to guarantee the Quality of hot forging press machine?

A1:We are ISO 9001-2008 certified company. we have the integrated system for industrial parts quality control. We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2:What's the Advantage of iPOWER hot forging press machine?

A2:Our advantage :

1. The technology is imported from Germany and we have experienced engineers who have been worked in this field for more than 20 years, and some new engineers who has production experiences, know-how the machine working in pratice.

2. High precision,most competitive prices, fast delivery.

3. With good company culture, our employees are responsible-oriented, friendly-oriented,and diligent-oriented. our machines are featured by strict tolerance, smooth finish and long-life performance.

Q3:what are the machining equipments?

A3:Our machining equipments include milling machines, turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, screw machines, cutting machines and so on.

Q4: What shipping ways you use?

A4:Generally speaking, we will ship them by sea. This way can save our customers a lot of freight fee.

Q5:What materials can you handle?

A5:Brass, bronze, copper,aluminum, titanium, for LPG Cylinda Valve, ball valve, plug valve, steam valve, stop valve, gas valve, etc.

Q6:Can you provide detailed proposal,photos, working viedo, and specifications of the machines?

A6: Yes, we can provide all detailed information of our machines. We can give full proposal after receiving drawing of the products.